Umgomo osebenzayo we umshini wokupakisha we-thermoformingukusebenzisa izici zokushisa noma ukuthambisa amashidi epulasitiki anezakhiwo ze-tensale zokushaya noma asuse impahla yokufaka ukwakha iziqukathi ezihambisanayo ngokuqamba okuhambisanayo, bese ulayisha imfucumfucu bese uqoqa ngokuzenzakalela imfucuza ngemuva kokusika futhi kwakheka. Kuqukethe ikakhulukazi izingxenye ezilandelayo:

Ukufudumezana-Ukwakha indawo

Ngaphambi kokubumba, fudumeza ifilimu elingezansi ukufinyelela amazinga okushisa adingekayo ukuze kuthambe futhi kuthambe, ukulungele ukwakha ngokushesha. Indlela yokubumba yehlukile ngokusho kobuchwepheshe bomenzi, okubonakalayo kwefilimu, kanye nokujula kwesitsha sakhe.

Lokhu okulandelayo kwethula izindlela eziningi ezivame kakhulu futhi ezisetshenziswa kabanzi zokwakha emishini yokufaka i-thermoforking:

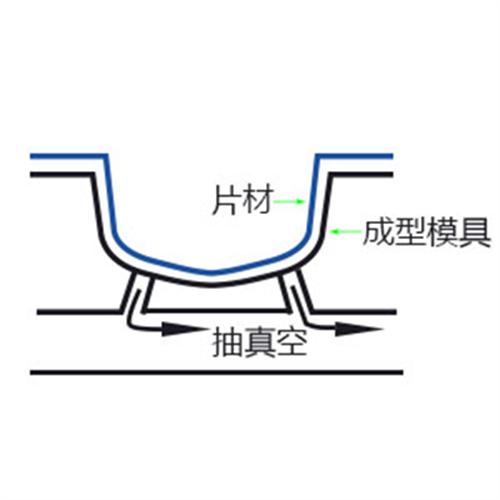

1) I-Vacuum: Ingcindezi engemihle yakha, i-vacuum evela ezansi kwesikhunta ukuze unamathisele ishidi lilingana nesiqukathi sokufaka, elilungele iziqukathi ze-twner.

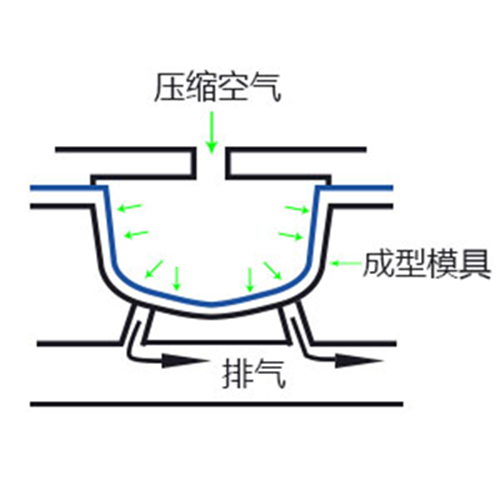

2) umoya ocindezelwe. Ukucindezela okuhle kwakha, engeza umoya ocindezelwe kusuka ngaphezulu kwegumbi lokushisa. Le ndlela inezidingo eziphezulu zobuchwepheshe futhi ilungele ukwelula amashidi amakhulu nokwakha iziqukathi ezijulile.

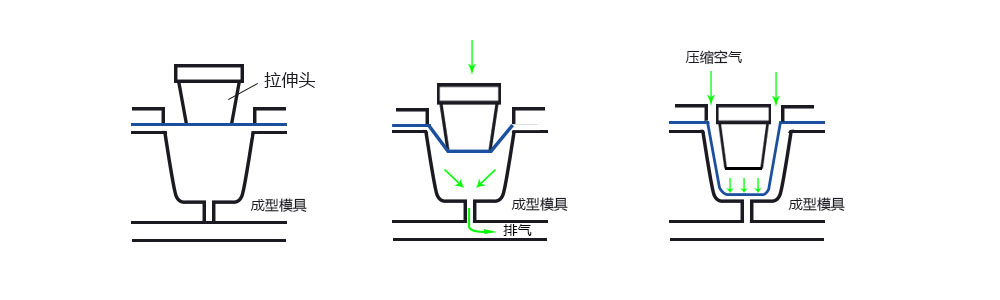

3) Faka indlela yokwelula yokwelula esekelwe ku-1 no-2. Umgomo oyinhloko ukuthi izingcindezi zomoya ezahlukahlukene zakhiwa ezinhlangothini zombili zeshidi. Ngaphansi kwesenzo sokucindezela okuhlukile, ishidi licindezelwa phansi eduze kwaphansi kwesikhunta esenziweyo. Uma ubunzima bokwelula noma ukujula bokwakha bukhulu ikakhulukazi, kuyadingeka ukwengeza umshini wokulahla osuluzayo ukuze usize ifomu. Le ndlela yokwakha inezidingo eziphakeme zobuchwepheshe zabakhiqizi. Ngaphambi kokuthi umoya ocindezelwe uxhumekile, ishidi elifudumele nelithambile futhi linwetshwe ngaphambili yikhanda leluliwe, ukuze isitsha esisunguliwe sinokujula okujulile kanye nobukhulu obukhulu bokuhlangabezana nezidingo zamakhasimende amaningi.

Ukwelula ukunwebeka kwakheka kwakheka

Ngalezi zindlela ezingenhla ezingenhla, isikhunta esenziwe saphola, sakhiwe esitsheni esifana nesimo sesikhunta.

Ngemuva kokuphola ngokuphelele, kwakhiwa esitsheni esifana nesimo sokubumba.

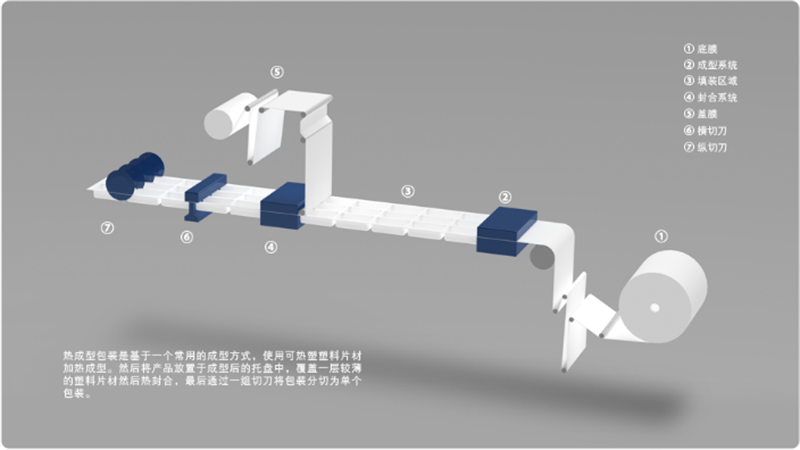

Inqubo esebenzayo yomshini wokufaka we-thermoforming ikhonjiswa kwisibalo esingezansi (ifilimu eliguqukayo):

I-AndroidBottom Film Area: Faka i-Coll roll ekhefini evuthayo njengoba kudingeka, qinisekisa ukuthi isikhundla silungile, futhi senze senze siqine. Yondla uhlangothi olulodwa lwefilimu elingaphansi phakathi maphakathi namaketanga amabili wokubhoboza kanye nesigubhu.

Indawo e-2.Forming: Idluliswa yi-chain, ifilimu elingezansi ifinyelela endaweni eyakhayo. Kule ndawo ngokuya ngezidingo zamakhasimende, ishidi liyafuthelwa futhi lelulwa ngezindlela ezintathu ezingenhla zokwakha (vacuum, umoya ocindezelwe, ukwelula ikhanda + umoya ocindezelwe + umoya ocindezelwe).

3. Indawo yokulayisha: Le ndawo ingahlonyelwa ngemishini yokugcwalisa okuzenzakalelayo noma ukugcwaliswa kwencwajana ngokuya ngezidingo zamakhasimende.

I-4.Sealing Area: Ifilimu elingezansi nefilimu ephezulu lifudumele, i-vacuum futhi livalwe kule ndawo (Faka umsebenzi we-inflate njengoba kudingeka), futhi izinga lokushisa lokubekwa uphawu lingashintshwa ngokuya ngezakhiwo zeshidi.

I-5.Cuting Area: Kunezindlela ezimbili zokusika zale ndawo ngokuya ngobukhulu befilimu: ifilimu eqinile yokusika ingcindezi, ifilimu eliguqukayo lokusika okuguqukayo nokude. Ngemuva kokuthi imikhiqizo ivaliwe, ithunyelwa kule ndawo yokusika nokukhipha.according kwizidingo zamakhasimende, singafaka imishini yokusiza njengokuhlunga, ukutholwa kwensimbi, ukutholwa okunesisindo nokunye ukwenza umugqa ophelele wokukhiqiza.

Ngemuva kweminyaka yocwaningo kanye nokwenza ngcono, umshini wokupakisha we-Utien Pack Thermoforming wakhe ngempumelelo iziqukathi ezijulile eziyi-150 mm, ngokunemba okuphezulu nokusatshalaliswa kwefilimu kwefilimu efanayo. Ngasikhathi sinye, ijubane lethu lokupakisha lifinyelele ezikhathini ezingama-6-8 ngomzuzu, ngaphambi kwalo lonke uhambo lwasekhaya.

Isikhathi sePosi: Dec-25-2021