1

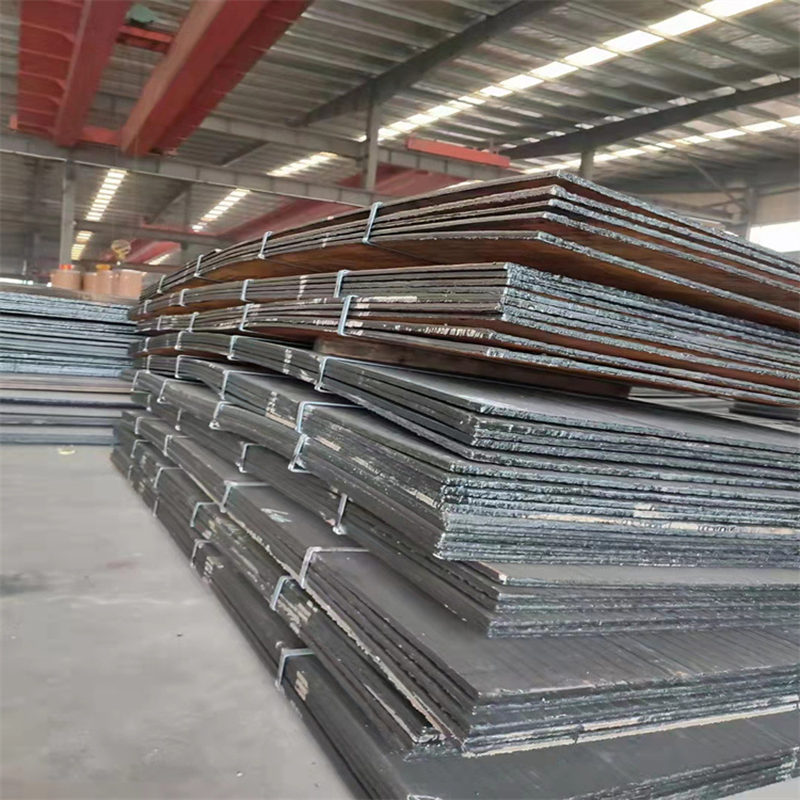

Gqoka ipuleti yensimbi engamelana ne-brathentint, okungukuthi ugqoke insimbi yensimbi engazweli, ingumkhiqizo okhethekile wepuleti osetshenziswa ngokukhethekile ngaphansi kwezimo ezinkulu zokugqoka. Ihlanganiswe neplanethi yensimbi ephansi ye-carbon kanye nongqimba olungamelana ne-alloy.

Iplatiti lensimbi elingavikeli phansi linezici zamandla aphezulu kanye nokuphikiswa okuphezulu. Ungqimba oluvimbela ukugqokwa kwe-alloy ngokuvamile luyi-1/3 kuya ku-1/2 ngobukhulu obuphelele. Uma usemsebenzini, i-matrix ihlinzeka ngezakhiwo eziphelele njengamandla, ubulukhuni kanye nobunzima bokumelana namandla angaphandle, futhi ungqimba oluvimbela ukugqokwa kwe-alloy lunikeza ukumelana kwezimo ezicacisiwe.

Kunezinhlobo eziningi zamapuleti ensimbi ezingavilisiwe, kufaka phakathi amapuleti ensimbi anqabile avinjelwe kanye namapuleti ensimbi aqothulwe aqothulwe. Isibonelo, ipuleti yensimbi engamelana ne-KNBEDITRURE iluhlobo lomkhiqizo owenziwe ngokuhlanganisa ubukhulu obuthile be-alloy ukugqokwa okuvinjelwe ngobulukhuni obukhulu be-carbon noma insimbi ephansi yensimbi ephansi noma i-low-alloy yensimbi enobunzima obuhle kanye ne-plastiki ngendlela yokusebenzisa i-surfacing. Amapharamitha wezobuchwepheshe wepuleti lensimbi engazweli ngokuvimbela okulandelayo: Ubulukhuni bama-vickers bungu-1700hv; Izinto ezibonakalayo ziyisisekelo sensimbi ephansi yekhabhoni, nezinye izinhlobo ze-surffing hard alloys ne-niobium carbide zinganikezwa ngokuya ngezidingo. I-chromium ne-boron alloy carbides icebile; Ubulukhuni besendlalelo esivimbela ukugqokwa kwenhlanganisela ngu-C62-65 HRC; Ubukhulu bangamamilimitha ayi-3 - 15; Okuqukethwe kwe-hard alloy kungaphezulu kwama-50%; Izinga lokushisa eliphakeme lingu-1000 ° C.

Ngaphezu kwalokho, iplate evimbela insimbi engazweli i-360 nayo inguhlobo lwamandla aphezulu kanye nepuleti elingamelana nelona elingamelana nokuvinjelwa. Kwenziwa ubuchwepheshe bokubulala inzalo futhi inamandla angcono namandla okuqina, kanye nokumelana okuhle nokuvimbela okuhle nokumelana nomthelela.

2. Ukusetshenziswa kwamapuleti ensimbi engavikeleki

2.1 uhla olubanzi lwezicelo zezimboni

Amapuleti ensimbi engavikeliswanga athola izicelo ezibanzi ezimbonini ezahlukahlukene. Embonini ye-metallurgical, zisetshenziswa emishini efana nama-crushers namabhande okuhambisa, ahlala ngaphansi kokuhlukunyezwa kanye nomthelela. Embonini yamalahle, baqashwa emalahleni amalahle kanye nezindawo zemishini yezimayini ukumelana nezimo ezinzima zokugqoka. Imboni kasimende isebenzisa amapuleti ensimbi anokugqokwa kwama-kilns kanye nokugaya amalambu ukuqinisekisa impilo yenkonzo ende. Embonini yamandla, asetshenziswa kumalahle amalahle kanye nezinhlelo zokuphatha ash.

Isibonelo, kusetshenziswa ipuleti yensimbi engasho lutho ngo-360 kusetshenziswa kabanzi emikhakheni efana nezimoto, izitimela, izindiza, i-metallurgy, imboni yamakhemikhali, ama-machroleum, ugesi, ukongwa kwamanzi, nokwakha. Ilungele izakhi ezithwala imithwalo emikhulu yomthelela emishini yezimboni ngenxa yokumelana kwayo okuhle kakhulu, ukumelana nomthelela, nokuphikiswa kokugqwala.

2.2 Ukusebenza Kakhulu Izindleko

Uma kuqhathaniswa nezinye izinto ezisetshenziswayo, amapuleti ensimbi anokufakelwa anikela ngentengo ephezulu. Yize izindleko zokuqala zamapuleti ezinsimbi ezingavikeleki ezigqokile zingase ziphakeme kancane kunezinye izinto zendabuko, ukumelana kwazo okuphakeme nokuqina nokuqina kokuqina kokulondolozwa okubalulekile ekuhambeni kwesikhathi. Isibonelo, inkampani esebenzisa amapuleti ensimbi angenayo enqubweni yayo yokukhiqiza ingahle ithole ukwehliswa kwesikhashana sokulungiswa kwemishini nokubuyiselwa esikhundleni, okuholela ekukhiqizweni okwengeziwe kanye nokonga izindleko.

Ngokusho kwemininingwane, impilo yenkonzo yamapuleti ensimbi engavikeliswanga kuvame kaningi isikhathi eside kunaleyo yamapuleti ajwayelekile ensimbi. Lokhu kusho ukuthi izinkampani zinganciphisa izindleko zabo ezibonakalayo nezindleko zokulungisa ngokuhamba kwesikhathi. Ngokwengeziwe, ukusebenza okuhle kakhulu kwamapuleti ensimbi anokugqokwa kunciphisa ingozi yokuhluleka kwemishini nokubambezeleka kokukhiqiza, okwenza ngcono ukuthuthukisa izinzuzo zabo zezomnotho. Ngenxa yalokhu, izimboni eziningi kanye nabakhiqizi bakhombisa okuncamelayo kwamapuleti ensimbi engazweli.

3. Ukuhlukaniswa kwezinto ezibonakalayo zamapuleti ensimbi engavikeleki

3.1 izinhlobo ezijwayelekile zezinto ezibonakalayo

Amapuleti ensimbi avimbela ukugqokwa ajwayele ukwenziwa nge-surfacing alley izingqimba ezivimbela ukugqokwa ebusweni bensimbi evamile ye-carbon noma insimbi ephansi. Kukhona namapuleti ensimbi avinjelwe avinjelwe kanye namapuleti ensimbi aqothulwe acijisiwe. Isibonelo, ipuleti lensimbi elivimbela ukugqokwa kwenhlanganisela lenziwa ngokuhlanganisa ubukhulu obuthile be-alloy egqoke ungqimba olungamelana nobulukhuni obuphezulu nokumelana kahle kwensimbi.

3.2 izinhlobo ezahlukene zezimpawu

Kunezinhlobo ezintathu zamapuleti ezinsimbi ezingamelana nokugqokwa: uhlobo lwenhloso ejwayelekile, uhlobo oluvimbela umthelela, nohlobo olungamelana ngaphansi kwezinga lokushisa.

Iplatiti evimbela insimbi engazweli elivikelekile ngokuqinile inokusebenza okuzinzile futhi ilungele izimo zokugqoka ezijwayelekile. Inokumelana okuhle kokuvikeleka namandla alinganiselayo. Amapharamitha wezobuchwepheshe angafaka izinga elithile lobulukhuni, ngokujwayelekile cishe ngo-50-60 HRC. Ukwakheka kwezinto ezibonakalayo kuvame ukuqukethe izinto ezifana ne-chromium ne-manganese ukuthuthukisa ukumelana nokugqoka. Ekusebenzeni, ingamelana nezinga elithile le-abrasion futhi lisetshenziswa kabanzi ezimbonini ezinjengomshini.

Iplate evimbela insimbi engavikeli umthelela iklanyelwe ukubekezelela imithelela esindayo. Inobunzima obuphakeme kanye nokumelana okuhle kakhulu komthelela. Okuqukethwe kuvame ukuqukethe izinto ze-alloy ezithuthukisa ukumelana nomthelela wayo. Isibonelo, amanye amapuleti ensimbi angenamelana navimbela ukugqoka angavikeleki angaba nobulukhuni baku-45-55 HRC kodwa ngokumelana nomthelela omkhulu. Lolu hlobo lufanele izinhlelo zokusebenza lapho imishini ingaphansi kwemithelela evamile, njengasezimboni zezimayini nasezokwakha.

Ipuleti lensimbi elingavikeleki eliphakeme elivimbela ukugqokwa okungavikeleki lingamelana namazinga okushisa aphezulu. Yenziwe ngezinto ezikhethekile ze-alloy ezingagcina ukuqina emazingeni okushisa aphezulu. Amapharamitha wezobuchwepheshe angafaka ukushisa okuphezulu okuphezulu kokufika ku-800-1200 ° C. Ukwakheka kwezinto ezibonakalayo kuvame ukuqukethe izinto ezifana ne-nickel ne-chromium ukuqinisekisa ukumelana okushisa kakhulu. Ekusebenzeni, kusetshenziswa kabanzi ezindaweni eziphakeme zokushisa ezifana nezinsimbi nama-kilns ezimbonini ze-metallurgical kanye nosimende.

Isikhathi sePosi: Oct-31-2024