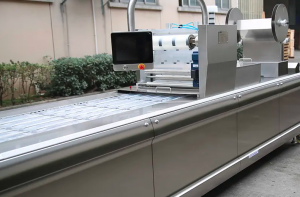

Imishini yokupakisha ye-Thermoforming VacuumDlala indima ebalulekile embonini yokufaka, uqinisekise ukuthi imikhiqizo igcinelwe ngokuphephile futhi ivalwe ngempumelelo ukuze ilondoloze ubusha futhi banwebe impilo eshalofini. Ukuqinisekisa ukumiswa isikhathi eside kanye nokusebenza okuphezulu kwale mishini, ukulungiswa okufanele kubalulekile. Kulesi sihloko, sixoxa ngamathiphu athile asemqoka wokugcina umshini wokupakisha we-thermoforming we-thermoforking.

1. Ukuhlanza njalo: Ukuhlanza njalo kubalulekile ukuvikela ukwakhiwa kokungcola, imfucumfucu kanye nezinhlayiya zokudla ezingxenyeni zomshini. Landela imiyalo yokuhlanza yomkhiqizi, engafaka ukusebenzisa izihlanza noma izixazululo ezithile. Naka ngokukhethekile izindawo zokubopha nokusika, njengoba noma yiziphi izinsalela kulezi zindawo zizothinta ikhwalithi yephakheji. Qiniseka ukuthi ugeza zonke izingxenye kahle futhi uvumele ukome ngaphambi kokusebenzisa umshini futhi.

2 Bheka imihlahlandlela yomenzi ukuthola i-lubricant efanelekile kanye nemvamisa yokuthambisa. Ukugcwala ngokweqile kudonsela ukungcola kanye nemfucumfucu, ngakho-ke qiniseka ukusebenzisa i-lubring ngokuqinile bese usula ngokweqile.

3. Hlola bese ubeka esikhundleni sezingxenye ezigqokwa: Ngezikhathi ezithile hlola umshini wezimpawu zokugqoka ezifana nemifantu, izimpawu ezigugile noma izikulufa ezivulekile. Ngokushesha buyisela noma yiziphi izingxenye ezilimele noma ezigqokile ukuvikela ukulimala okwengeziwe emshinini futhi ugcine i-airtight yokufaka. Gcina izingxenye ezisele ziseduze ukunciphisa isikhathi sokuphumula futhi uqinisekise ukukhiqizwa okungaphazanyiswa.

I-4. Clulisa umshini: Ukulinganisa njalo umshini kuzosiza ukugcina ukunemba kwayo maqondana nokushisa, ingcindezi, nesikhathi sokubekwa uphawu. Landela imiyalo yomenzi ukuze ulinganise kahle umshini. Ukulinganisa kungafaka ukuguqula izilungiselelo zokushisa, ukufaka ezinye izinto zokushisa, noma ukusetha kabusha isikhathi.

I-5 Qiniseka ukuthi opharetha bakho bomshini bajwayele ukusebenza komshini, imihlahlandlela yokuphepha nezinqubo zokulungisa. Nikeza ngezikhathi zokuqeqeshwa njalo ukuze uvuselele ulwazi lwazo futhi uqinisekise ukuthi bayakwazi ukukhomba nokuxazulula izingqinamba ezingaba khona ngesikhathi esifanele.

6. Landela imihlahlandlela enconyiwe yokusetshenziswa:Imishini yokupakisha ye-Thermoforming VacuumYiba nemihlahlandlela ethile yokusetshenziswa okunikezwe ngumenzi. Landela le mihlahlandlela ngokucophelela ukuze ugweme ukulayisha ngokweqile umshini futhi uzenze ukugqoka ngokweqile. Ungangeqi inani elinconyelwe amaphakethe ngomzuzu, ngoba lokhu kungagcizelela umshini futhi kunciphise impilo yaso.

7. Gcina ilogi yesondlo: gcina irekhodi yesondlo ukuqopha imisebenzi yesondlo, kufaka phakathi ukuhlanza, ukuthambisa, izingxenye zokubuyiselwa kwezingxenye, nokulinganisa. Leli rekhodi lingasiza ukulandelela umlando wokulungiswa komshini futhi akhombe noma yiziphi izingqinamba noma amaphethini aphindaphindwayo. Buyekeza izingodo njalo ukuze uqinisekise ukuthi imisebenzi yokulungisa iyaqhubeka njengoba kuhleliwe.

Ekuphetheni, ukulungiswa okujwayelekile kubalulekile ekusebenzeni kahle kanye nokuphila isikhathi eside komshini wokupakisha we-thermoforming Vacuum. Ngokulandela lezi zeluleko zokugcina, ungagcina imishini yakho isebenza kahle, inciphise isikhathi sokuphumula futhi ikhiqiza ukupakishwa okuphezulu. Khumbula ukuthintana umhlahlandlela womenzi wemiyalo ethile yokulungiswa, futhi njalo wenze ukuphepha kube okubaluleke kakhulu lapho usebenzisa le mishini.

Isikhathi sePosi: Jun-29-2023